Unlocking the Power of Data-Driven Insights & Analytics for Sustainable Manufacturing

Sponsored by: Makersite

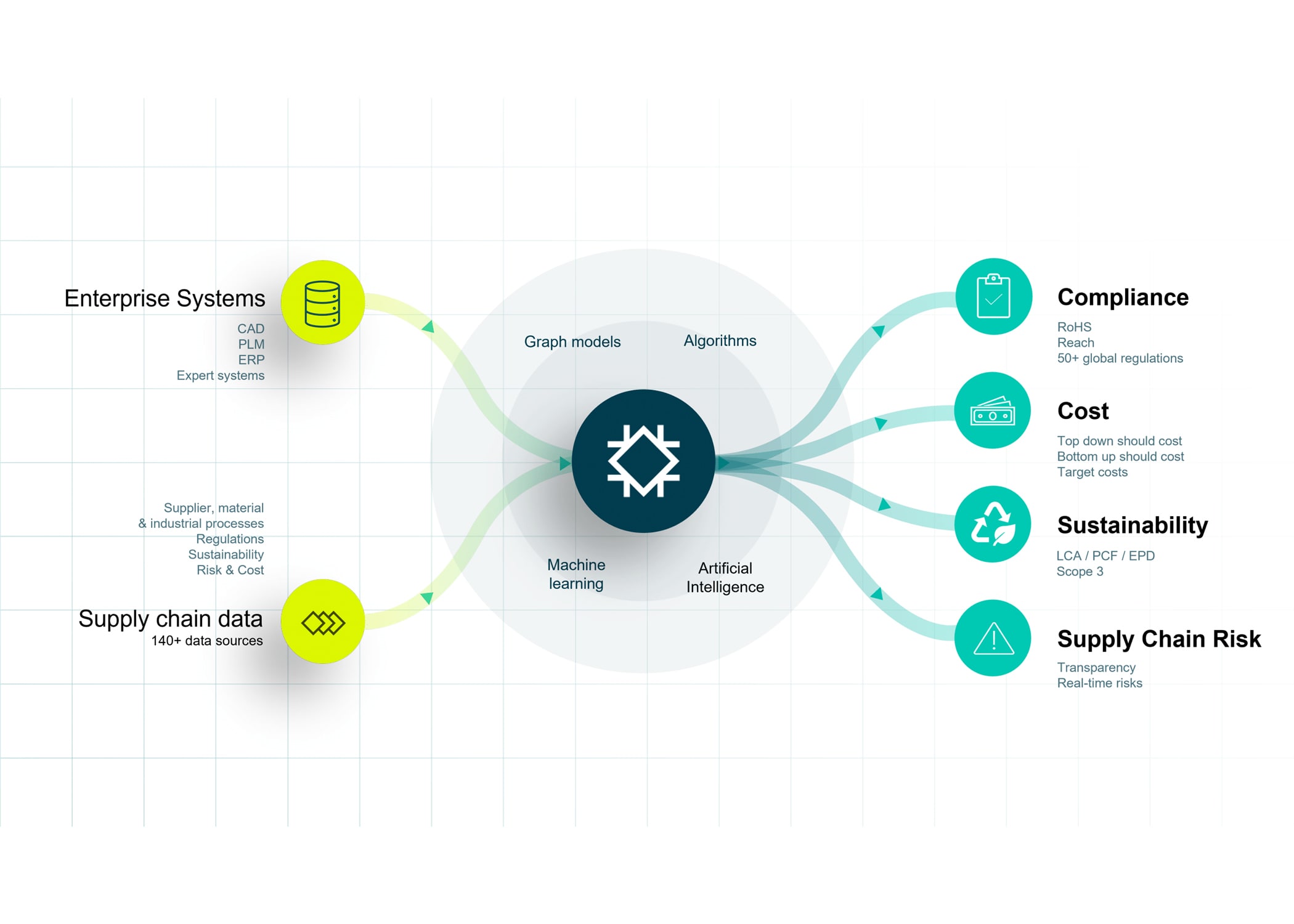

At NAEM’s TECH25 Conference, we are demonstrating how Makersite helps enterprises overcome these hurdles with an AI-driven approach to sustainability and lifecycle management. By leveraging real-time data integration, dynamic lifecycle assessments (LCAs), and supply chain analysis, organizations are empowered to move beyond estimations and make scientifically grounded decisions that balance sustainability, compliance, and cost efficiency.

Overcoming Key Challenges in Sustainable Manufacturing

Driving sustainability in manufacturing requires tackling complex technical and operational hurdles. Here’s what organizations face:1. Data Complexity and Fragmentation

Modern supply chains involve countless suppliers, regions, and data formats, making it challenging to establish a centralized, reliable, and traceable sustainability data system. Without a comprehensive view of your data, it’s impossible to measure the impact of sustainability initiatives and identify areas for improvement.

2. Lack of Real-Time Insights

Sustainability is an ongoing process, but traditional reporting methods often rely on outdated or incomplete data. Without real-time insights, organizations struggle to make informed decisions that can positively impact sustainability outcomes. Similarly, regulatory requirements for sustainable manufacturing are constantly evolving, making compliance a moving target. Organizations need a reliable and efficient way to stay ahead of changing regulations and ensure compliance across their operations.

3. Evolving Regulatory Demands

Regulators around the world are tightening regulations and increasing enforcement for environmental compliance. For businesses operating in multiple regions, staying compliant with varying standards is a constant challenge. Emerging policies like the EU’s Corporate Sustainability Reporting Directive (CSRD), California’s SB 253, and SEC climate disclosure requirements demand precise, transparent reporting of Scope 1, 2, and 3 emissions. Organizations need robust systems to stay compliant and accountable.

4. Limited Visibility into Scope 3 Emissions

The largest share of an enterprise’s carbon footprint often lies in Scope 3 emissions from upstream and downstream operations. Without actionable, real-time insights, businesses struggle to accurately measure, manage, and reduce these emissions. Addressing these challenges requires innovative, data-driven solutions that empower organizations to lead in sustainability while meeting regulatory demands and operational goals.

Embracing Data-Driven Solutions to Drive Sustainability

By integrating centralized data repositories with automated lifecycle assessment (LCA) workflows, manufacturers can leverage real-time analytics to drive science-based decision-making. This approach enables dynamic optimization of environmental impact, cost structures, and regulatory compliance, ensuring alignment with sustainability frameworks such as the GHG Protocol and emerging ESG disclosure mandates.1. Comprehensive Supply Chain Intelligence

Traditional sustainability efforts are hindered by fragmented, outdated data, making it difficult to adapt to supply chain changes. Makersite transforms this process by integrating real-time data from over 50 environmental impact databases, supplier networks, and regulatory sources. The result is a dynamic, living digital model of an enterprise’s supply chain, enabling businesses to assess and optimize sustainability impacts in real-time rather than relying on static estimates.

2. Automated Lifecycle Assessments for Smarter Decisions

Conventional lifecycle assessments (LCAs) are time-intensive and quickly outdated, limiting their effectiveness. Utilizing AI automates LCAs will deliver real-time insights into environmental impacts at both the product and supply chain levels.

This allows manufacturers to:

- Evaluate materials and suppliers instantly to identify lower-impact options.

- Model design changes and analyze sustainability trade-offs before production.

- Optimize procurement strategies by balancing environmental, financial, and regulatory factors.

Read More about the benefits of Microsoft’s new LCA Methodology with Makersite

3. Ensure Compliance with Global Sustainability Regulations

As ESG reporting grows increasingly complex, manual compliance tracking is no longer viable. Enterprises need to be empowered to automate regulatory compliance by seamlessly connecting supply chain and emissions data to evolving frameworks such as CSRD, SEC climate disclosure rules, and industry-specific ESG mandates. Ensuring proactive approach eliminates last-minute data bottlenecks, ensuring compliance is both efficient and reliable.

Register for Makersite’s next Masterclass: Navigating Material & Substance Compliance

4. Embed Sustainability into Manufacturing and Product Design

Sustainability must be built into processes—not added as an afterthought. Enterprises must equip engineering and procurement teams to analyze environmental and cost impacts early in the product lifecycle, reducing waste and maximizing material efficiency.

For industries like electronics, automotive, and industrial manufacturing, our data-driven insights ensure design decisions align with regulatory and corporate sustainability objectives. This integration turns sustainability into a strategic advantage, driving both innovation and competitive differentiation.

Key Strategies for EHS&S and Manufacturing Leaders

Unlock the full potential of sustainable manufacturing by moving beyond static reporting to embrace real-time data analytics and AI-driven solutions. These cutting-edge tools allow leaders to gain deeper insights, optimize processes, and drive measurable improvements in sustainability efforts. Here are the key actions to consider:1. Centralize Data for Supply Chain Transparency

Adopt unified, AI-powered systems that consolidate sustainability data from across your supply chain. These platforms ensure information is accurate, traceable, and easily actionable, enabling leaders to identify inefficiencies, minimize environmental impact, and build trust with stakeholders through transparent reporting.

2. Use Real-Time LCAs for Continuous Optimization

Transition away from traditional static lifecycle assessments (LCAs) and embrace dynamic, scenario-based LCAs powered by real-time data. These tools allow you to evaluate the environmental impact of your products and processes on an ongoing basis, helping uncover opportunities for improvement and driving continuous progress in sustainability initiatives.

3. Integrate Sustainability Across Operations and Design

Embed sustainability at every stage of product design, procurement, and supply chain management. By taking a holistic approach, you can achieve tangible, measurable outcomes, such as reducing material waste, lowering carbon emissions, and designing products with a lower environmental footprint. This integration also aligns teams around shared sustainability goals, fostering collaboration and innovation.

4. Automate Compliance to Stay Ahead of Regulations

As ESG regulations rapidly evolve, staying compliant can become a significant challenge. Proactively track and align with these requirements through automation technologies that streamline workflows and reduce risk. Automated systems not only ensure you remain compliant but also free up valuable time and resources, allowing teams to focus on broader sustainability strategies.

By implementing these strategies, EHS&S and manufacturing leaders can position their organizations to thrive in an increasingly sustainability-focused marketplace while making a meaningful impact.

The Future of Sustainable Manufacturing

Manufacturing is at a turning point. As sustainability requirements grow and regulations become stricter, businesses need data-driven, scalable solutions to deliver real results. Makersite provides tools that combine supply chain modeling, lifecycle insights, and advanced analytics to transform sustainability challenges into opportunities for innovation and efficiency.Learn how data intelligence and AI-powered tools are shaping the future of sustainable manufacturing at NAEM’s TECH25 Conference.

Discover how Makersite can help your business improve regulatory compliance, reduce environmental impact, and boost operational efficiency by visiting makersite.de.

About the Author

Makersite

Makersite is a Product Lifecycle Intelligence software tailored for the global manufacturing industry. Harnessing groundbreaking AI technology, Makersite empowers product teams to efficiently manage sustainability, cost, and compliance, turning complex multi-level criteria analysis and decisions at scale from months to minutes. Founded in 2018 by industry veterans, the Stuttgart-based company boasts team members across Europe, Asia, and North America supporting a customer portfolio of industry trailblazers such as Microsoft, Schaeffler, Cummins, and Vestas.

Makersite simplifies intricate product and supply chain data tasks by creating digital twins of product models. Enriched with global supply chain data, these models offer a comprehensive view of a product's environmental, cost, and compliance impact throughout its lifecycle. Makersite accelerates the product development process, allowing teams to effectively identify cost-saving and eco-friendly strategies in real-time. The result is a faster and more collaborative approach to product development. Visit makersite.io to learn more about Makersite's innovative solutions.

Makersite simplifies intricate product and supply chain data tasks by creating digital twins of product models. Enriched with global supply chain data, these models offer a comprehensive view of a product's environmental, cost, and compliance impact throughout its lifecycle. Makersite accelerates the product development process, allowing teams to effectively identify cost-saving and eco-friendly strategies in real-time. The result is a faster and more collaborative approach to product development. Visit makersite.io to learn more about Makersite's innovative solutions.